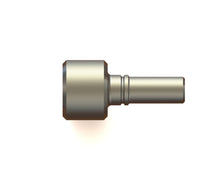

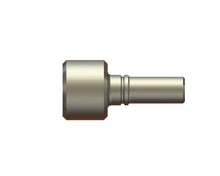

The impact cap slides into the female threaded end of all shafts (opposite the point or male threaded end). It is the part that receives the impact blows from the sledge hammer or jack hammer in order to drive the tool through the ground. After the shaft with the impact cap is driven in and another shaft needs to be connected then the impact cap is removed by pulling it out. If it is to tight to pull out by hand then it may be tapped with whatever object to loosten it. The next shaft is then threaded into the shaft where the impact cap was just removed, and the impact cap is re inserted into the female end of the newly connected shaft, and so on...